- MenuRetour

- Fake Menu

- Industrie

- Sport & Santé

- Applications Cliniques

- Contact

- Fake Menu

Comment protéger les capteurs de force flexibles des forces de cisaillement

Les capteurs de force ultra-minces - comme les capteurs FlexiForce - sont des composants électroniques intégrables intéressants pour les dispositifs intelligents réagissant à la force. Leurs propriétés mécaniques leur permettent de s'intégrer dans des espaces restreints.

Toutefois, en fonction des exigences de votre application, vous devrez peut-être prévoir des méthodes pour préserver le capteur des forces de cisaillement afin de prolonger sa durée de vie. Voici quelques suggestions :

1. Assurez une mise en charge uniforme

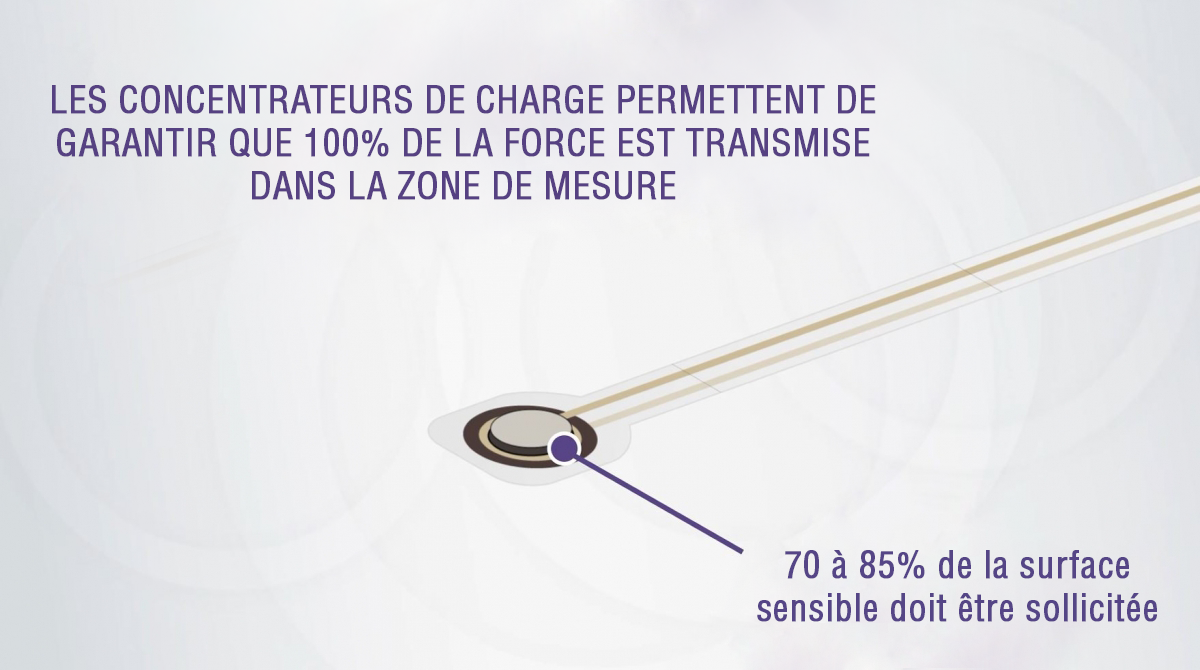

Le moyen le plus efficace de garantir une répartition uniforme de la force sur votre capteur est d'utiliser un concentrateur de charge, ou "puck". Le collage de différents matériaux rigides sur la zone de mesure du capteur, comme du néoprène, du polycarbonate, du delrin et de l'acier inoxydable, constitue une méthode efficace pour concentrer la charge sur le capteur.

En général, nous recommandons de suivre une règle "100-70", où 100% de la force est concentrée dans 70 à 85% de la zone sensible du capteur. Cette procédure permet non seulement d'obtenir des mesures de force plus répétables, mais aussi de protéger le capteur si la position de l'applicateur de la force ou de l'actionneur change au fil du temps. Des concentrateurs de charge sont disponibles à l'achat sur notre site.

2. Tenez compte des forces de cisaillement dans votre conception

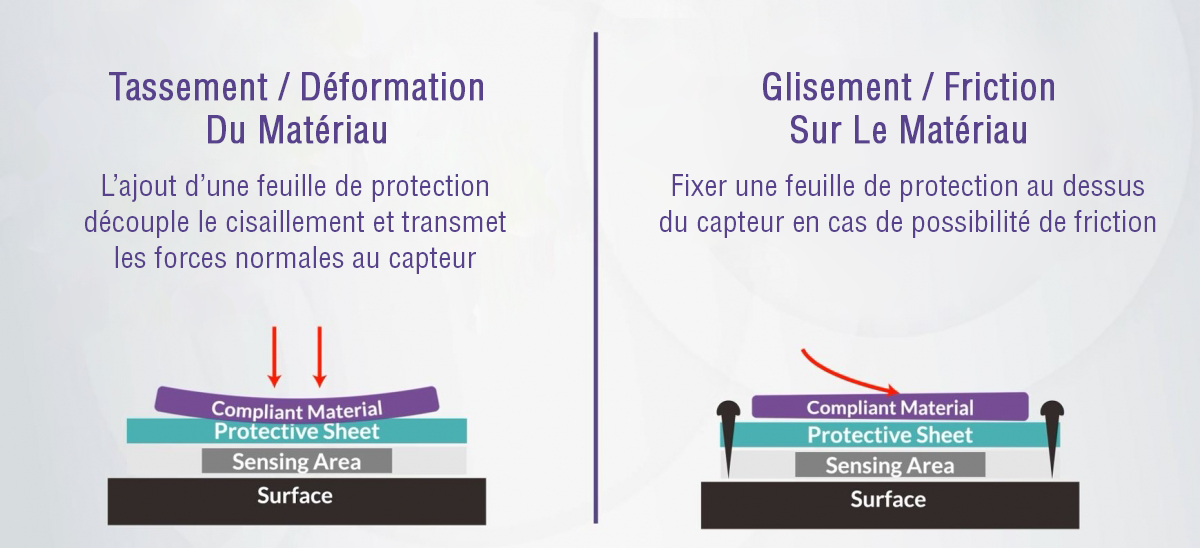

Les ingénieurs qui envisagent d'intégrer des capteurs de force flexibles dans leurs projets ont tout intérêt à anticiper et à éviter les forces de cisaillement, c'est à dire toute force non normale au plan de la zone sensible du capteur. Un cisaillement excessif peut entraîner une dégradation de la sensibilité du capteur au fil du temps.

Là encore, associer un concentrateur de charge à votre capteur contribuera grandement à réduire l'effet du cisaillement dû aux charges non normales.

Des mesures supplémentaires peuvent toutefois être nécessaires si votre application utilise des interfaces souples. Ces matériaux peuvent se déformer ou glisser, ce qui peut provoquer un cisaillement à la surface du capteur.

Pour pallier ce problème, envisagez de coller ou de fixer un matériau de protection dur pour découpler le cisaillement et transmettre les forces normales au capteur.

3. Utilisez des moyens de fixation sûrs pour maintenir les capteurs

Nous vous recommandons vivement d'utiliser un ruban adhésif double face pour coller les capteurs de force. Cela permet non seulement d'obtenir une surface plane, mais il s'agit également d'une solution économique pour la production de masse.

En revanche, vous devez toujours éviter les époxies ou les sprays à prise dure, car ils peuvent introduire des points de pression indésirables susceptibles de perturber les transmissions de force.

Voici une courte vidéo démontrant ces recommandations :

Articles similaires

Etendue de mesure d'un capteur de pression Tekscan

Etendue de mesure d'un capteur de pression Tekscan Les 5 capteurs de cartographie de pression les plus utilisés

Les 5 capteurs de cartographie de pression les plus utilisés Les 5 critères pour sélectionner le meilleur capteur de cartographie de pression

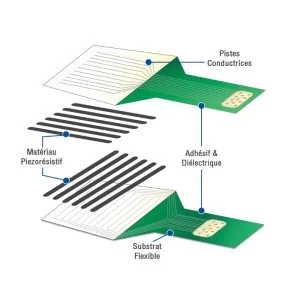

Les 5 critères pour sélectionner le meilleur capteur de cartographie de pression Anatomie d'un capteur de cartographie de pression

Anatomie d'un capteur de cartographie de pression La cartographie de pression Tekscan face aux autres technologies de mesure de contact

La cartographie de pression Tekscan face aux autres technologies de mesure de contact Technologie piezorésistive de cartographie de pression

Technologie piezorésistive de cartographie de pression