- MenuRetour

- Fake Menu

- Industrie

- Sport & Santé

- Applications Cliniques

- Contact

- Fake Menu

Comment mesurer des forces plus importantes avec le capteur tactile FlexiForce ?

Si vous avez parcouru notre gamme de capteurs FlexiForce™ standard, vous avez sans doute remarqué que nos capteurs sont désignés par une gamme de force. Par exemple, le modèle A201 qui est le capteur standard le plus courant, est proposé dans trois gammes de force : 4 N, 111 N, et 445 N (1 lb, 25 lb, et 100 lb respectivement). Toutefois, ces plages de force sont libellées spécifiquement pour le cas où l'électronique utilisée pour alimenter les capteurs est à un niveau de base.

Les capteurs tactiles FlexiForce disposant d'une gamme dynamique très étendue, ils peuvent en réalité mesurer des forces bien supérieures à leur désignation standard. En réalité, le capteur A201 de 445 N (100 lb) peut être utilisé pour acquérir des forces allant jusqu'à 4 445 N (1 000 lb) en modifiant sa tension d'alimentation et en ajustant la résistance de retour de l'amplificateur de conditionnement du signal.

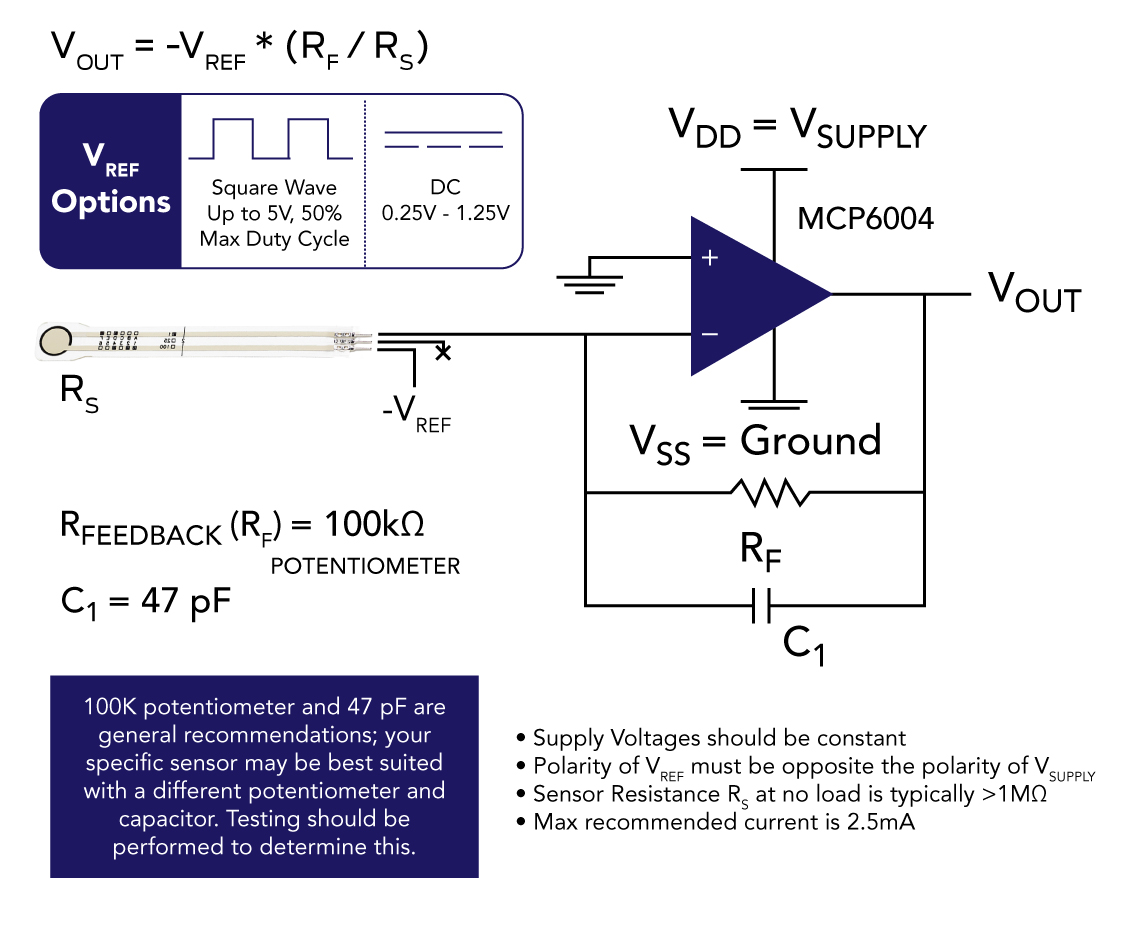

Figure 1 : Circuit recommandé pour un capteur tactile FlexiForce (Op-Amp inverseur, ou double source).

Comment ajuster la plage de force du capteur FlexiForce ?

La figure 1 représente le circuit que nous recommandons pour alimenter un capteur tactile FlexiForce. Nous recommandons d'utiliser un circuit ampli-op inverseur (double source). Toutefois, si votre application ne peut pas supporter deux alimentations, reportez-vous à nos autres circuits recommandés dans notre Guide des meilleures pratiques d'intégration électrique.

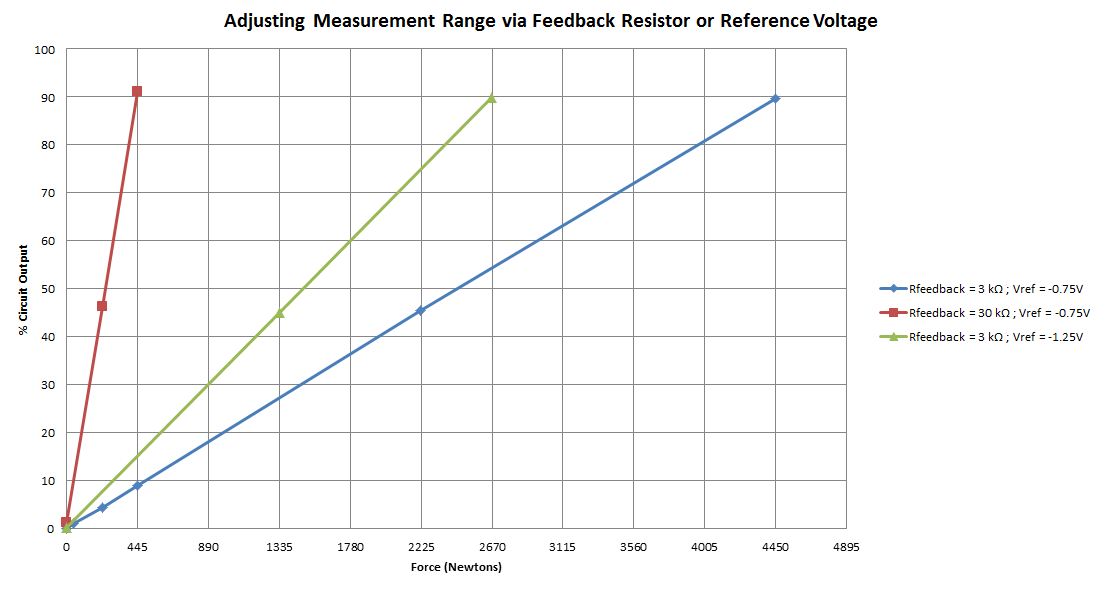

La sensibilité réglable peut être implémentée en utilisant un potentiomètre, ou un convertisseur numérique-analogique (CNA) pour ajuster la tension de référence. Pour un capteur donné, vous pouvez augmenter ou diminuer la plage de mesure en ajustant la tension de référence et/ou la résistance de retour. La figure 2 illustre ce principe. La sensibilité du capteur peut être augmentée pour la mesurer des forces plus faibles en augmentant la tension de référence ou la résistance de la résistance de retour.

Figure 2 : Le graphique ci-dessus montre comment le même capteur tactile FlexiForce peut mesurer des plages de force plus élevées lorsque la résistance de rétroaction ou la tension de référence est modifiée. La sortie reste linéaire dans tous les scénarios.

Produits associés

Système de mesure de force USB ELF™

Système de mesure de force sans fil WELF™

Articles similaires

Etendue de mesure d'un capteur de pression Tekscan

Etendue de mesure d'un capteur de pression Tekscan Les 5 capteurs de cartographie de pression les plus utilisés

Les 5 capteurs de cartographie de pression les plus utilisés Les 5 critères pour sélectionner le meilleur capteur de cartographie de pression

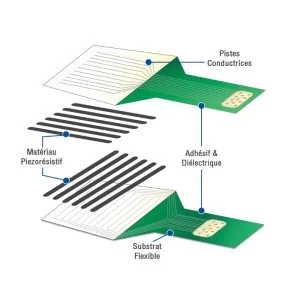

Les 5 critères pour sélectionner le meilleur capteur de cartographie de pression Anatomie d'un capteur de cartographie de pression

Anatomie d'un capteur de cartographie de pression La cartographie de pression Tekscan face aux autres technologies de mesure de contact

La cartographie de pression Tekscan face aux autres technologies de mesure de contact Technologie piezorésistive de cartographie de pression

Technologie piezorésistive de cartographie de pression